Since the planks are staggered the first plank in each run will be a different length (either 50mm, 100mm or a full 150mm plank.) So to start with I had to cut and sand some 50mm and 100mm planks and then I began glueing and fitting them. I started out using the same method as before to clamp them down while drying..however as I got to outer planks this doesn;'t really work as the clamping planks bend in the middle, making them a bit useless when glueing multiple planks at once. I haven't come up with a catch all solution to this, but I have just used clamps directly where I can, or simply get a block of wood and put "something" (see photo below for some amusing examples) on it to hold the plank down. Rough and ready I know, but it gets the job done!

Some photos below showing the progress.

24 planks with clamping;

39 planks fitted:

39 planks fitted:

The current position. Don't worry, the tea that was in the mini eggs mug is now safely in my belly! No chance of a terrifying spillage!

The current position. Don't worry, the tea that was in the mini eggs mug is now safely in my belly! No chance of a terrifying spillage!

I think I'm going to spend a good chunk of this evening making a big batch of planks. I'm going to aim for a 5:1 planks to mugs of tea ratio.....going to have to find another mug though!

Jonny.

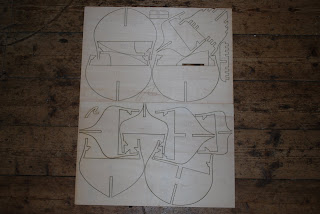

WAIT A MINUTE!! I can't believe I nearly forgot, but the fourth installment arrived this morning!! Not quite as exciting as before I suppose because I'm no where near being able to start on it!

Anyway here's what you get:

Not much in terms of parts, but plenty in terms of potential work time! The bag contains about a billion more pins and the bundle of wood is all 2x5 strips of basewood. This wood will be used to plank the hull.....new word coming here....freeboard. A bit of research tells me that the freeboard is the part of the hull which is above the waterline. All the hull below the water will be planked with a differed wood.

Not much in terms of parts, but plenty in terms of potential work time! The bag contains about a billion more pins and the bundle of wood is all 2x5 strips of basewood. This wood will be used to plank the hull.....new word coming here....freeboard. A bit of research tells me that the freeboard is the part of the hull which is above the waterline. All the hull below the water will be planked with a differed wood.So once I have finished planking the false deck I will be facing the daunting task of embarking on the hull planking. More on that later when I can pluck up the courage to admit that I'm going to have to do it!

Jonny.