However, we are now near enough settled in and my new workplace is all sorted! At least now I have my own desk so won't have to keep moving the ship and risk damaging it!

I don't have many photos to show my recent progress, but just to stay up to date I have done the following since my last post:

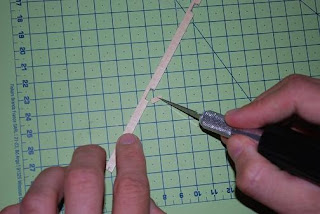

I bought a trusty dremel and went to work on the bow and stern parts to shape them for planking. I've got to admit I didn't really use a particularly efficient method for doing this. I simpy worked with a thin plank and laid it on the ribs in various places and then hacked away with the dremel where I felt it was needed. My plan is to make any small adjustments as I lay planks. The area that needed the most work was the around the knightheads. I had to hack away quite a bit of wood to get it in the state in the picture below.

You may also notice in the photo above that 2 of the outer stern collars fell off while I was working! Sods Law of course that only one of them turned up! I think the other one may have gone on an adventure in the bin lorry!

Anyway, this provided the opertunity to do my first bit of "scratch" building, if you want to call it that! I just took a bit of scrap plywood and using my bone saw, dremel, files and sandpaper attempted to make a new one. I was fairly pleased with the result not perfect, but I'm happy for a first attempt!

I mentioned in my previous blog that I was going to add some balsa filler blocks to the bow, but I decided that this wouldn't be needed for the freeboard section, since the planks are very easy to bend and shape! So I will save that for doing the main hull.

So, next step was to start planking the freeboard (not sure if I've mentioned this already, but apparently the "freeboard" simply refers to the area of the hull above the water line.)

I have so far fitted 7 planks to the freeboard, 4 at the stern and 3 at the bow. I'm waiting for the glue to dry on the latest bow plank and will then fit the corresponding plank on the other side and will have finished the basic platform to plank all the freeboard.

I don't have any pictures of this yet, but will give a bried run through of how I am doing it and more detailed stuff later on. To ensure the plank if the correct height all the way along I marked a 25mm line on a piece of paper and then layed this paper on each bulkhead so that the edge was against the deck. I then marked with my knife the 25mm line onto the bulkhead. This marked the place that the bottom of the first plank must lie on each bulkhead. I then carefully glued and nailed the first plank along to the stern. I found it easiest to work from the middle bulkhead, and put on pin in each bulkhead working backwards. I had some trouble with the last bulkhead which I haven;'t yet fixed, but I'm leaving for the moment until I can see how the other planks will lie. One tip I found useful was to use a pair of tweezers to hold the pins in place and then hammer them gently in. I found that the pin pusher was too inaccurate for this job, and the tweezers meant I could be very accurate which my placement of the pin.

I found that the stern planks needed very little bending, however I still soaked these planks for quite a while so they had some suppleness, but found that they would bend freely when fixing them to the ship. However, with the bow planks they required quite a bit of bending. I have heard from various sources that the best way to bend is to use heat. I have found it very effective the bend planks by wetting them first and then holding the main area to bend over the spout of a boiling kettle to really soften them up. I them simply used the outside of the hot kettle to bend the plank round. Very simple but effective. Once I had bent the bow planks in this way I fitted them in the same way as the stern planks.

Another piece of advice that I should pass on is the alternate the side of the ship you are planking. So I did the first bow plank on the starboard side, then immediately did the equivalent plank on the port side. This meant that I could check that they were symmetrical. I actually found the because I wasn't careful in checking when I attached the planks to the first winding frame, while the planks started and finished in the same place, they didn't actually follow the same curve. I was then able to adjust this early and now they look fairly symmetrical! I can now lay planks on top of these and I can just check that they are lining up at the bow and the rest should fall into place. Lots of planks to go but some of the hard work is done.

I'll post again soon with lots more pictures and much fewer words!!

While I here I should add that while I'm still working on issue 4 from Model Space, I've actually received issues 5 and 6. They are very confusing to say the least. I'll report what I received, but won't say anything more about what I think about it!

Issue 5 was simply 80 more basswood planks to continue with the freeboard planking and also to plank the inside of the bulwarks. The instructions for issue 5 also include the construction of the footboard to hold the ship once it has been planked. However, there were no parts with my order so I couldn't actually do this!! However, these parts did turn up in issue 6...and nothing else! The instructions for issue 6 are for planking the hull with sapele planks, but I don't have any!! Having posted on the forum I think this is what I was supposed to get, but it is a bit strange. Having now seen the instructions for issue 7 and 8, they continue to deal with the hull planking, so I imagine that the next couple of installments will just be sapele planks, so it will all work itself out at the pace I'm working, but it was very confusing for a while!

Anyway, enough ramble, more ship building!

Cheers,

Jonny.